Seven ways to leverage Business Intelligence to increase your manufacturing business’ production efficiencies by double-digits

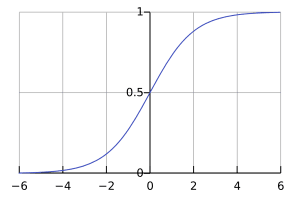

There is an important curve: f(x) = 1/(1+e^-x), the Sigmoid (or S) curve, with the shape of the Greek Sigma letter, which describes a large number of phenomena in the universe:

At first the output increases slowly along with the input – so slowly that it seems almost constant. Then it starts to change faster, then very fast, then slower and slower until it becomes almost constant again.

The Sigmoid curve captures the shape of phase transitions of all kinds, including the processes of ice melting, water evaporating, writing a bit of memory to a hard disk, an ion channel opening in a cell, the inflationary expansion of the early universe, paradigm shifts in science, the spread of new technologies, rumors, epidemics, revolutions, the fall of empires and the evolution of your company (if you’re doing it right).

I think that the Sigmoid curve describes how manufacturing companies are currently embracing automation in the fourth industrial revolution, which is also called Industry 4.0 – where automation and data exchange converge in manufacturing technologies.

The Sigmoid curve describes manufacturing’s overall industrial development. The exponential, or steep part of the curve, represents the Fourth Industrial Revolution. We’re currently at a crucial turning point – the beginning of the exponential movement. If a company isn’t tracking along with the trends that are powering this movement, then it won’t leverage the technology that drives the others exponentially – and the company will fall behind its competition.

Where we are right now in history is exceptional because we are very close to the inflection point of the curve where the rules will dramatically change. Only those who adopt this new technology will survive – and thrive.

If you’re a leader of a production company, observe this curve closely. You’ll reach the exponential part of the curve where the slope becomes steep very quickly. This is a critical juncture. If your company can optimize this small timeframe, it can overtake the biggest companies – but if you miss it (and that’s easy to do), you’ll most likely fall behind the competition. That’s why as a manufacturing company, it’s essential to research the new trends and technologies affecting the industry. This is true of other industries too, of course. But for this piece we’ll focus on manufacturers.

OK, which trends?

One of the most important trends of the Fourth Industrial Revolution is industrial robotics. Yes, we are reading about robots everywhere, but we’re not seeing artificial intelligence technology moving the needle on production statistics. An interesting Bloomberg article points out the missing correlation between the U.S.’s labor productivity and the increasing number of industrial robots: “…The number of industrial robots is increasing rapidly, but shipment stats, a good indicator of investments, are showing only minor improvements. Labor’s contribution to output growth is also more or less the same as before the financial crisis.”

Based on this fact you might deduce that the whole Industry 4.0 is an overhyped lie. My conclusion is slightly different. I believe that the new industrial era doesn’t rely on just robots; in fact, it means mostly not the robots. It means the other forms of AI that can and are revolutionizing industries.

Want to learn more?

Stay Up-to-date

Sign up now for new trends and get an insightful case study related to business intelligence.

Put the other forms of AI to work for you

Here are seven ways you can use cheap artificial intelligence (generally in your Business Intelligence system if you have a good one) to reliably increase your productivity:

1. Track employees’ locations

To optimize productivity, you can track your employees’ locations inside the buildings and then leverage your Business Intelligence system to both visualize the positions and then find correlations between their positions and the actual state of operations. For example, you might discover that a CNC spindle is running, but the dedicated worker is drinking his/her coffee in the mess hall – for me, this does not equate to efficiency.

2. Monitor KPIs with alerts

Do you (or your managers) get an automatic alert when one of your most important customer’s orders is experiencing a business-hurting delay? You already have heaps of KPIs in your system that measure financial and working efficiencies; you can set alerts up very easily in the Business Intelligence system. Each KPI has its limit points, the measured data points above or below these points are considered extreme. You can look up these KPIs every morning when you sit down at your desk. Or if you have a good BI solution, you can set up alerts for these values and get real-time warnings through email or text message. So you’ll always know when you’re in range – and when you’re not. That’s what I call control of your production efficiency.

3. Predict orders and raw material prices

This article describes how Dyntell Bi’s prediction capability works. But how can use it to foresee your manufacturing needs? Based on your past orders, machine learning algorithms will learn the pattern of your data and forecast expected future orders. Using this (and your BOM), your ERP or BI can calculate the required amounts of raw materials for the future, as well as when to start the procurement. If you have enough historical raw material price data, Dyntell Bi can even predict the possible price change in raw materials too, so you can buy the right amount at the optimal time. This invaluable information can save you great amounts of time and money.

4. Predict currency exchange rates

If you have subsidiaries abroad or your raw materials and parts are coming from other countries, you probably know the importance of exchange rates. Dyntell Bi offers a free site where you can see our hourly or daily predictions for a given exchange rate. Based on this, you can decide when to exchange any foreign currency to USD.There are a lot of rates available, so if you don’t find your desired currency rate in your solution, please let us know, and we’ll set it up for you.

5. Use predictive maintenance

You may already be using this, but I’m guessing you’re only using a small part of this big capability. Predictive maintenance differs from preventative maintenance, which seeks to decrease the likelihood of a machine’s failure by performing regular maintenance. Predictive maintenance, however, relies on data. It uses machine learning to make predictions about future outcomes.

Current tools just rely on the machine’s vibrations, but if you interface all of your machine’s parameters to a BI, then you can analyze the correlation between your waste numbers and other outputs and the machine’s internal data. Based on these data points, you can continuously fine-tune your machine parameters to achieve their best performance. For your older machines, you can also use sensors to garner useful data.

6. Detect fraud

Data entry is hard work and your employees aren’t infallible. You have to know which data is correct and which may have an error or even an intentional cheat. That’s where BI comes in. Extreme values can be interesting even in an appropriate dataset, but Dyntell Bi goes one step further. It has a unique outlier analysis algorithm that automatically detects possible fraud in your data and alerts you immediately. Stop the surprise factor!

7. Optimize your power consumption

Your contract with your energy broker will have a maximum power consumption value. If your consumption exceeds this limit, the energy price generally increases considerably. So it’s in your best interest to keep the consumption under this value. If you have a modern BI solution, you can set this limit and the software will predict the possible overconsumption and send you an alert even BEFORE the event occurs. How’s that for proactivity?

Our team behind Dyntell Bi is ready to set these charts up for your organization. Please drop us a message here if you need a demo or have questions.

And if you want to see more ways to increase your productivity with BI, read on.